0

You have 0 items in your cart

- Home

- Health & Safety Items

- SERVICES

- WHAT CAN WE PRINT?

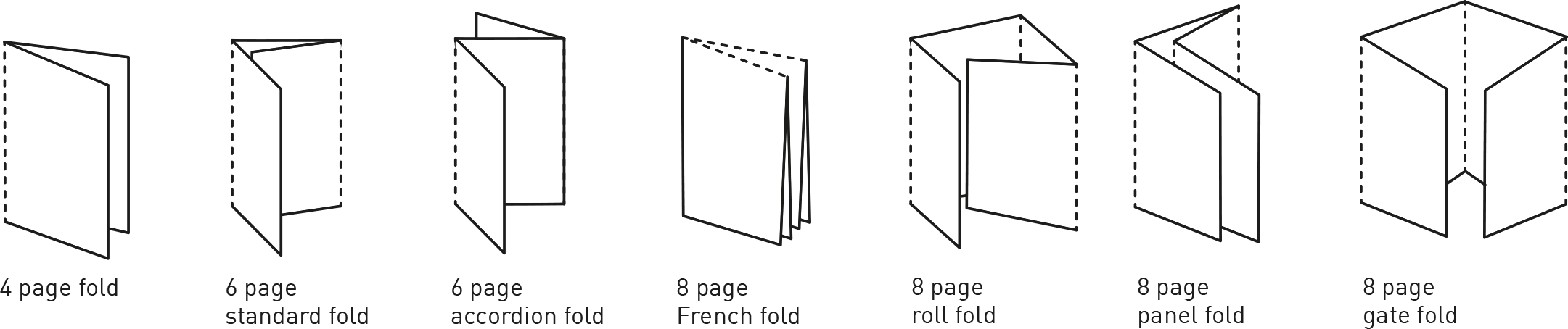

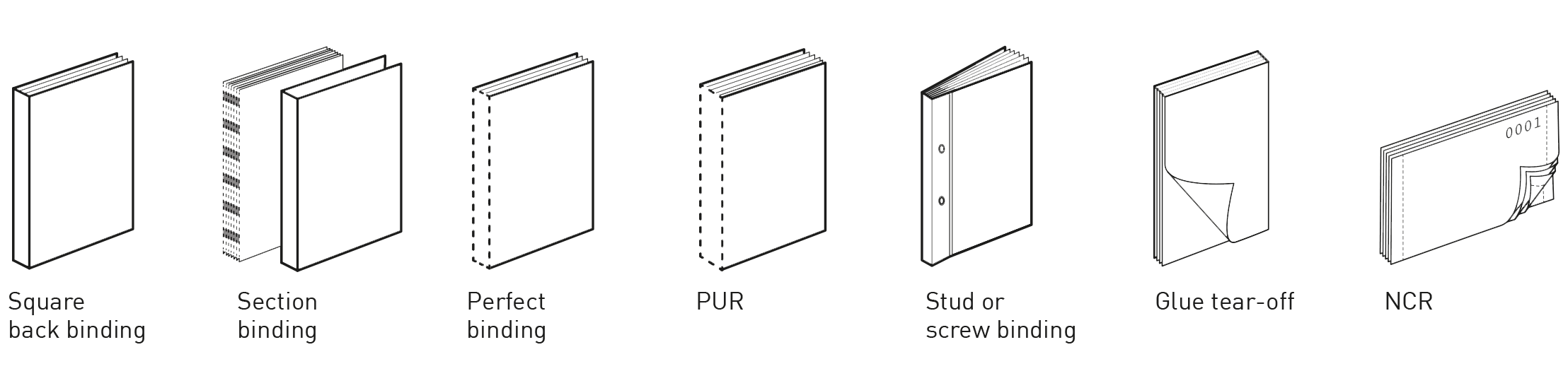

- Brochures, Reports, Phonebooks/Zines & Booklets

- Leaflets & Flyers

- Pull-ups, Popups and Roller Banners

- Notice and Display Boards

- Exhibitions, Displays and Stands

- Greetings Cards, Postcards & Invites

- Board Games Mats, Events and Tournaments

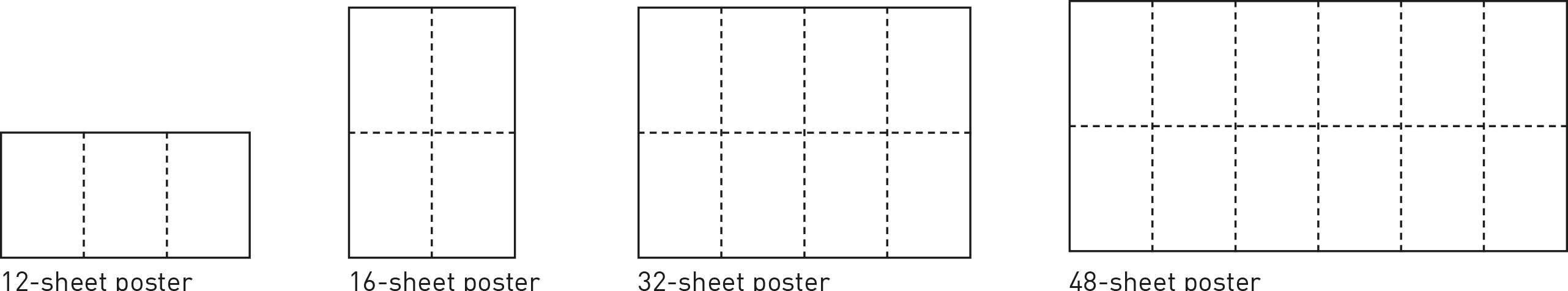

- Posters

- Stationery

- Manuals

- Packaging

- NCR Forms and Duplicate Pads

- Hangers and Swing Tags

- Direct Mail

- Special Finishing

- Promotional Merchandise

- Resources

- GET IN TOUCH

- Testimonials

- BLOG

- SHOP